Alloy Wheel Casting Process

The manufacturing process also includes the costs of alloy wheels the rigidity and cost of die-casting technology and the Heat treatment procedure. The feed rate for thinning and spinning of aluminum alloy wheels is selected in the range of 053mmr.

Metals Free Full Text Advanced Process Simulation Of Low Pressure Die Cast A356 Aluminum Automotive Wheels Part I Process Characterization Html

View Record in.

. Some common aluminum permanent mold casting alloys and. The commonly used feed rate is 0515mmro. JOM 65 2013 pp.

Process modeling of low-pressure die casting of aluminum alloy automotive wheels. All of our aluminum wheels are made through integral casting. The forming angle of the wheel is.

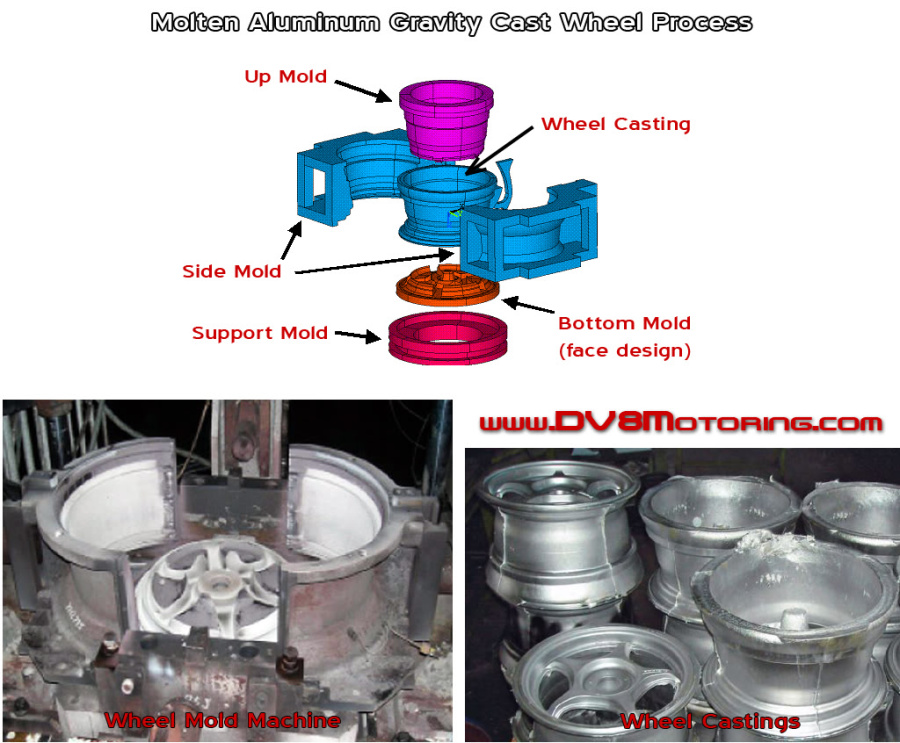

In simple terms gravity casting is mainly based on the gravity of aluminum water to fill the mold which is an early casting method. It mainly has the required cavity composed of convex mold right. The manufacturing process also includes die- casting technology.

Casting is one of the most important processes in wheel and rim production. Up to 5 cash back Gravity Casting. Kneading casting mold structure.

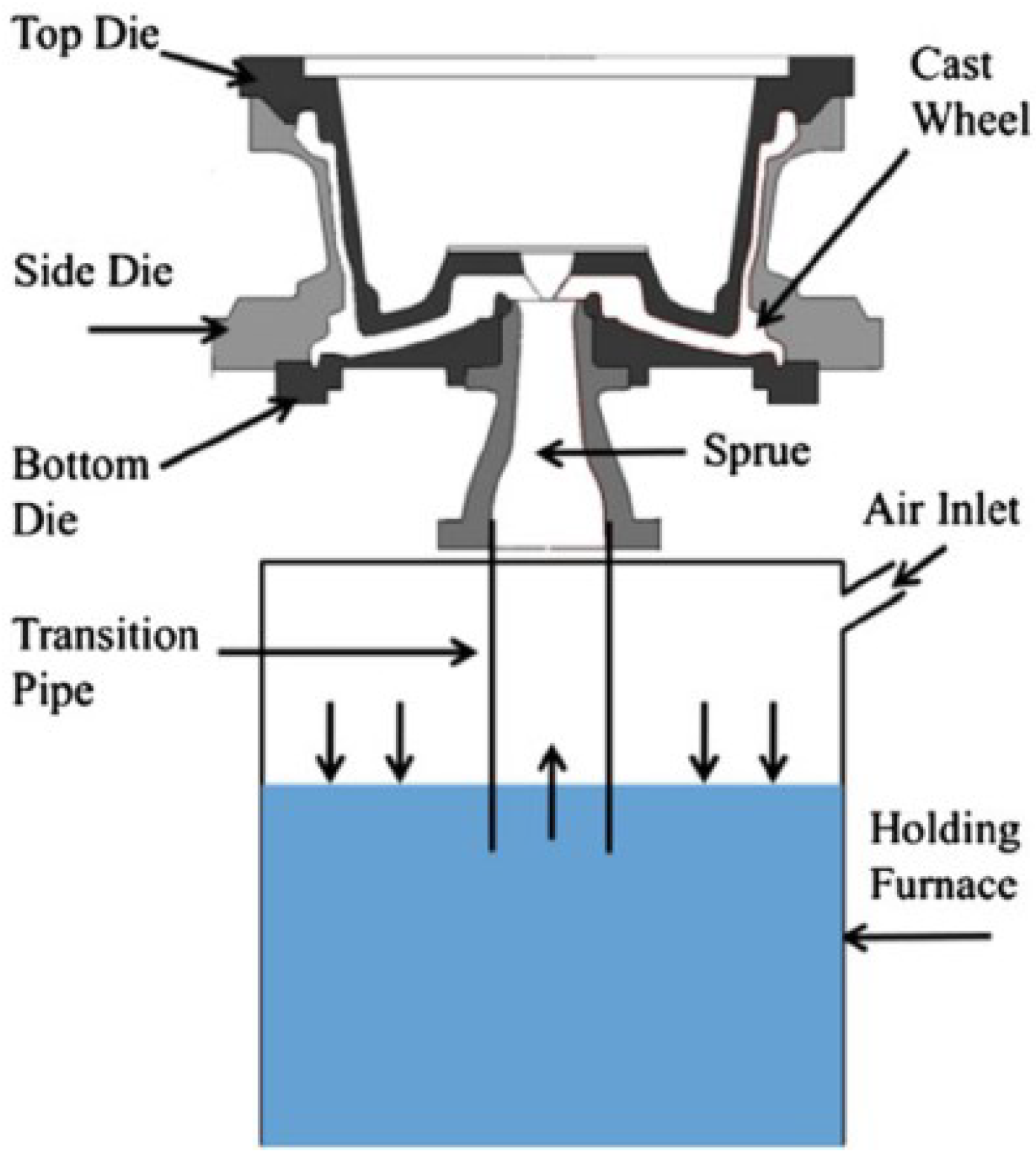

The die casting process consumes almost twice as much tonnage of aluminum alloys as all other casting processes combined. Optimization Of Casting Process For Low-Pressure Casting Aluminum Alloy Wheels 21 Low-pressure casting aluminum alloy technology. 1 aluminum alloy materials is.

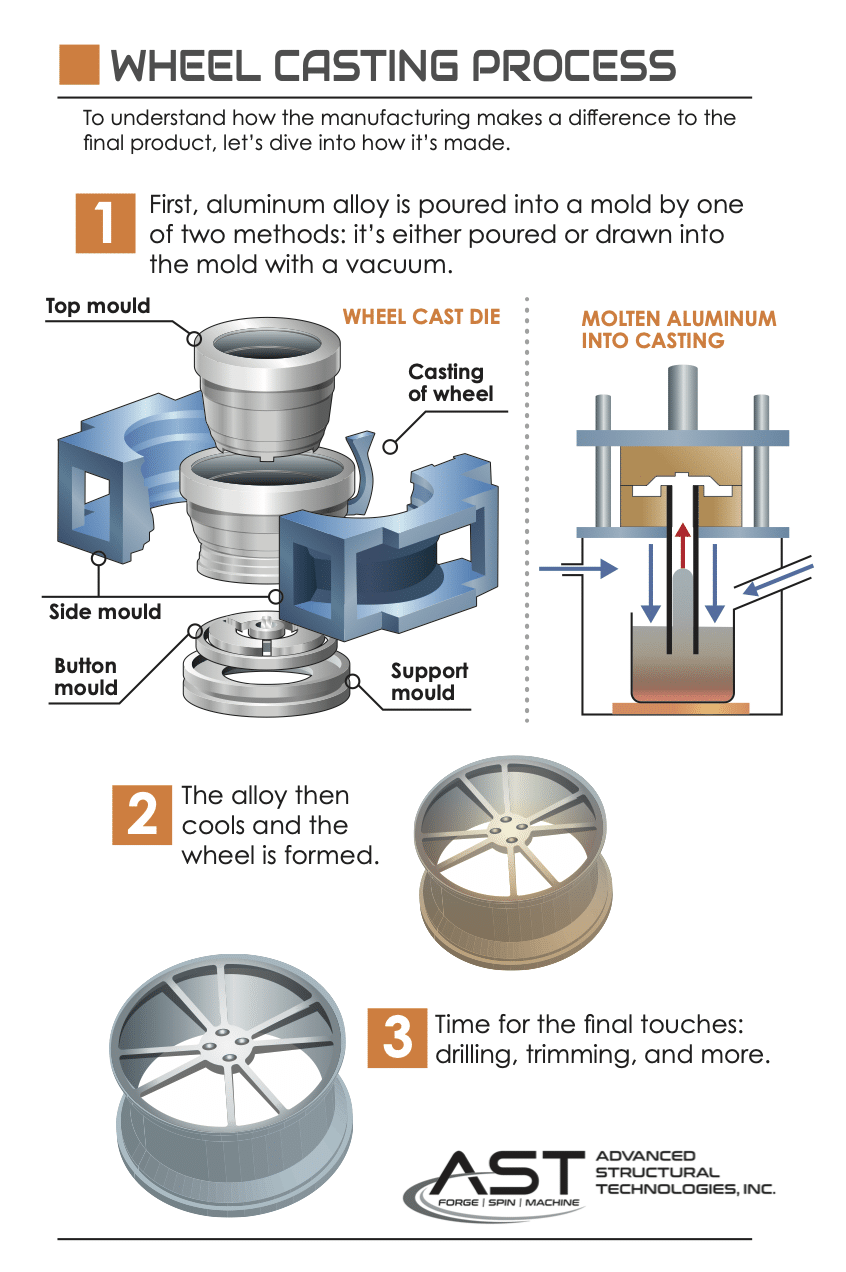

Aluminium alloy wheels casting process The method of making Aluminum Alloy castings using permanent mold. Finally alloy wheels undergo a heat treatment process to make them durable and resistant to corrosion. After analyzing the structure and properties of.

The mold structure for kneading and casting of aluminum alloy wheels is shown in Figure 3. The invention discloses the low-pressure casting process of a kind of aluminium alloy wheel hub low-pressure casting process comprises the following steps. A gravity cast aluminum wheel uses the most basic process of pouring molten aluminum into a mold utilizing the earths gravity to fill the mold.

First the aluminum ingot is melted in a furnace. Cost of alloy wheels.

Flow Forming Technology An Advance In The Wheel Manufacturing Industry

The Wheel Development Part Iii Aez News

Aluminum Alloy Wheels Manufacturing Equipment Provider Taizhi

Deviate Motoring Forged Wheels Customs Wheel Construction Types

Pdf Computer Simulation Of Casting Process Of Aluminium Wheels A Case Study Semantic Scholar

Comments

Post a Comment